Using the theory of gas-liquid mass transfer, the waste gas can be purified by chemical washing, which is called chemical deodorization. In the packed tower, the malodorous gas runs through the packing gaps, and is absorbed by touching with the absorbent sprayed onto the filler, finally descend to the bottom of the tower. While the clean air be treated get into the atmosphere through the exhaust pipe at the top.

Starts up fast and operational flexibility.

Has obvious effect on high concentration odor.

Operate stably, and will be little influenced by surroundings.

Suitable for purification of acidic and basic waste gas, or treatment of tail gas with high odor concentration.

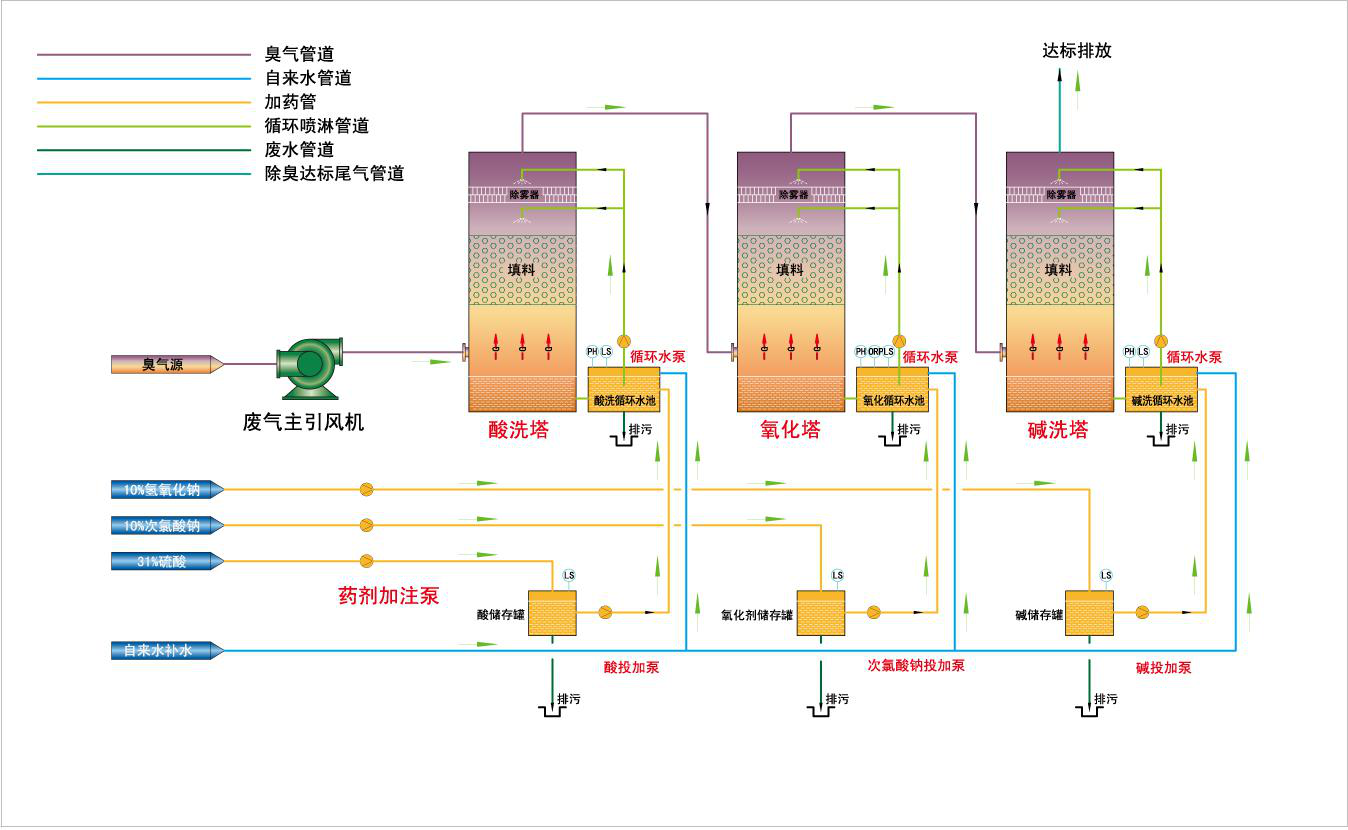

Wet padded bed absorber is the most commonly chemical scrubber tower, which has downstream, countercurrent and cross-current modes. For example, in the countercurrent circulating filled tower, the malodorous gas enters from the bottom of the tower, runs upward through the packing gaps, and is absorbed by the liquid that enters from the top of the tower and is sprayed onto the packing, finally, falls to the lower part of the filled tower with the absorption liquid. While the clean air that has been treated enters the atmosphere through the exhaust pipe. In order to completely remove the malodorous substances in the exhaust gas. To remove the odorous substances completely from waste gas, chemical washing deodorization usually adopts the multi-stage chemical scrubbing of acid and base. A typical flowchart is shown below:

| Device model | Processing capacity (m3/h) | Outer dimensions (Φ,H)(mm) | Equipment resistance(KW) |

| NFBU-L-3000 | 3000 | 1500,3700 | 200~300 |

| NFBU-L-5000 | 5000 | 1500,4400 | 200~300 |

| NFBU-L-8000 | 8000 | 1800,4700 | 200~300 |

| NFBU-L-10000 | 10000 | 1800,5500 | 200~500 |

For other specifications, please contact our technical engineers and customize according to site conditions.